MARIPOSA HISTORICAL SOCIETY

Mariposa, California

My Stamp Mill Training for “Millman”

I started restoring my first stamp mill in April of 1996. This activity is covered in one of my posts titled “Swallow Mine 5-stamp Restoration”. We spent 4 years sandblasting, priming, painting, and assembling the mill. Once the mill was at the point of running I searched for another mill that we could learn from its operation.

I found my first operating stamp mill at the Mariposa Historical Society in Mariposa, California back in August of 2000. The Museum is located in the heart of the gold rush country in California on Route 49. This was made famous from the prospectors involved with the gold rush of 1849. I found that the museum operated the 5-stamp mill periodically for school groups and other groups of individuals. We got a group of stamp mill volunteers together and went to Mariposa in late April 2001 to get trained on operating stamp mills. We all trained on the operation of the mill and learned a lot more about the components, maintenance, and how they actually ran the mill.

The museum was established on the current site in 1972, along with the stamp mill that came from the Golden Key Mine that actually operated until 1953. The picture below shows the monument constructed by the E Clampus Vitus organization. This organization was established after the 1849 Gold Rush and today they have chapters in several western states and recognize mining and other historical sites. They are also a social group and among other things helps our injured veterans with the “Annual Injured Soldier Fundraiser”.

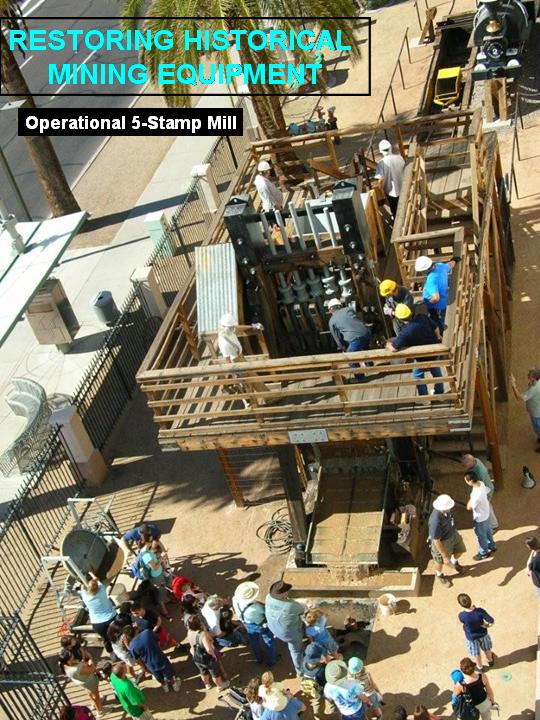

The museum has an excellent group of devoted volunteers who worked very hard to put together the 5-stamp mill on the museum grounds that we trained on. Just recently they continued their vigilance in keeping the mill in top shape by replacing the uprights and much of the lumber on the mill. You can see that they completed a lot of work to replace the timbers. The replacement of the uprights required that they totally remove the stamps and most of the superstructure to replace the timbers. Excellent Job!

When I first went to the museum there was only one stamp mill on the property. Since then they have obtained a 1-stamp, 2-stamp, and a 10-stamp mill that they intend to make operational. They are currently working on the 2-stamp and have it standing with the stamps installed. They have a lot of work ahead of them, but I think they will succeed in their efforts. They need to build the jackshaft and obtain a motor. The feeder also needs to be installed. Below are two pictures taken of the two stamp in July 2012.