Shoe

& Die Needs Both of these items are a very

important piece of the stamp mill and without them the mill ceases to operate.

Miners were constantly adjusting and changing shoes and dies out on the mill.

Depending on how hard the host rock is determines how often you have to adjust or

change both components. Remember, they had to maintain a specific crush height.

The shoes and dies had anywhere from 6" to 9" of wear material.

The

(10) new shoes below have about 8” of good wear material and the dies have

about 6" of wear material. Remember, also that the shoes wore down faster

than the dies. That is the reason for the difference in wear material quantity.

The picture below was taken in Ballarat at the Sovereign Hill 10-Stamp Mill in

south eastern Australia.

Shoe

& Die Materials The

following information was used for operating stamp mills back in the day where

they were run 24/6 as production mills. It states in “Stamp Mill A Treatise on Practical Stamp Mill & Stamp Mill

Construction” under the Shoe Topic that Shoes are made of cast iron, forged

steel or chrome steel, the last being the best material.

Shoes wear down faster than dies,

therefore he suggested that you use shoes made from chromium and the dies made

of a good forged steel. This will give you a longer life expectancy and less

labor and time to change out the shoes.

All of the above information is for a “production”

mill. The mills that I have worked on are run only for 15 to 20 minutes for maybe

once and week to once a month or so. The wear will be negligible. I have been

running a 10-stamp mill for over (7) years on an average and there is

negligible wear on the shoes and dies. Depending on the cost of the materials

we could go with a “forged steel” material and would suit us fine.

Making

Casting Molds The shoes

and dies are cast from molds. The shoe and die molds are made from wood that

forms a sand casting around the mold, the mold removed and then metal poured

into the casting. There are a couple of factors that go into the making of

shoes and dies with their associated thicknesses and diameters. The following is

an explanation of some methods of how the molds are made:

NOTE: I would like to recognize Dale McBride

for all of his work on coming up with the multiple layer designs for the shoe and

die molds. He spent many hours perfecting the design and building the forms in

his shop. This project would not have come to reality without Dale’s knowledge and

expertise.

Shoe

& Die Thicknesses Back

in the day the millmen would adjust the tappets to maintain the correct crush

zone during operations. The first thing that needs to be said is we “do not”

like moving tappets. Most of the tappets have been rusted on the stamp stem for

many years and they are very hard to move, once you move them, they do not want

to stay in place, and finally there is a breakage possibility. Most of the restorations

I have worked on do not have dies and tappets of the correct size and when

there are, they are all different sizes that would require tappet adjustment. Sometimes

there are no shoes or dies and you have to start from scratch. To make things

easier we would like to be able to make different size shoes and dies to obtain

the proper crush zone. The shoes would have a minimum thickness and then you

could add pieces to the mold to make the desired size. This could be done for

both the shoes and dies and would only require one mold. The drawing below

shows the stacked ¾” removable pieces.

Shoes

Sizes We have dealt

with many sizes of shoes and dies with diameters 6”, 8”, 8 ½”, 9” and 9 ½”.

Most of the shoes were 8 ½” to 9 ½” in diameter. You can have a shoe little

over or undersized and get away with it. The cone diameters on the shoes are

different sizes, but you can always use different size wood shims to make up

for the diameter differences. I have placed a drawing of a shoe with the most

common dimensions. This will probably work for any of the standard 8” projects

that are presently in progress. The following considerations were taken for the

shoe molds:

Shoe

Removal from the Casting

The shoe needs to be tapered so that the casting will slide out of the sand mold.

The shoe will sit in the mold with the cone facing down. The taper of 1/8” over

the 6” should be plenty to allow removal of the form and later casting from the

sand mold.

Multiple

Shoe Sizes We have made

molds with (4) ¾” removable pieces to make multiple shoe sizes for various applications.

The pieces will be held on the mold with bolts sized for each thickness. This

will allow us to get the proper crush zone of 5” between the bottom of the shoe

and the top of the die without adjusting with the tappets.

The drawing below shows the shoe mold. I

think we have covered all aspects and have decided to go with forged steel in

the discussion above. It appears that the shrinkage of the steel should be a

factor, so we will take that into consideration later in the discussion.

Dies The dies are a little more restrictive

since some mortar box producers do not make a” standard” size. With the dies the

mortar boxes are pretty much a standard length of 57” on the outside, but the

inside width becomes an issue when you have smaller dimensions.

The

following considerations were taken for the die molds:

Die

Removal from the Casting

We have tapered the die so that the mold will slide out of the sand casting and

also slide out of the casting once poured. It seems the taper of 1/8” over the

6” is enough.

Multiple

Die Sizes We have made

a mold with (4) ¾” removable pieces to make multiple shoe sizes for various

applications. The pieces will be held on the mold with bolts sized for each

thickness.

Casting shrinkage I would like some help on how much larger I

need to make the mold is we used the forged steel material. The table below

shows the metal shrinkage %.

The drawing below shows

the die mold. I think we have covered all aspects. We have decided to go with

forged steel in the discussion above and need to know how much larger the

dimensions should be for the shoe and die.

DIE MOLD

The

pictures below show the finished die and shoe molds. The shoes and dies can be

made different thicknesses by removing or adding layers of wood. The cones can

also be removed and smaller or larger cones can be installed if needed.

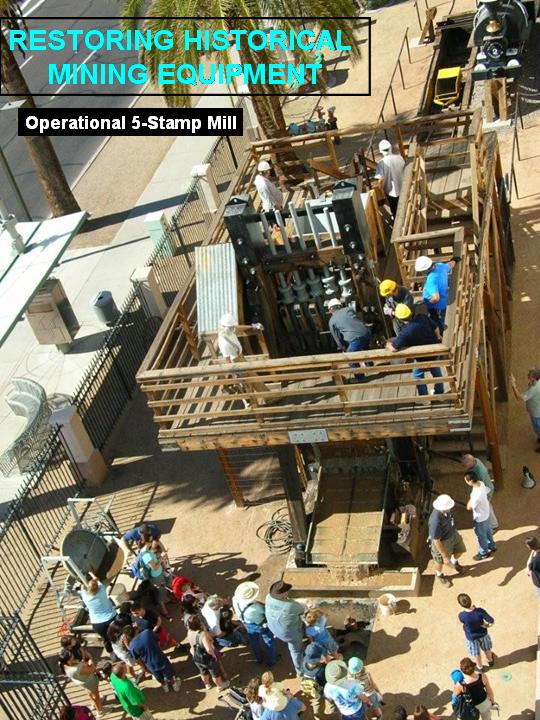

This

process will be used at the Gold King Mine in Jerome, AZ since they need

different sizes shoes and also the cones are different. We can make a different

shoe cone for all 5 shoes that have different boss dimensions. I have never

seen a mill with the extreme differences as the Gold King Mill.

Gold

King Boss Dimensions We

found that the bosses on the Gold King Mine dimensions were varied and we

needed to find out if one cone could be fabricated to fit the cones into the

boss. Dale made up a cone that used the smallest cone dimension of the five

bosses and sent it to me with several different shims to see what size cone/s

would work.

The pictures

below show how we will figure the angle inside the boss. The device will be

placed across the bottom of the boss and the angle measured. The angle on the

cone is about 83°. This device will be used to make sure that we get the angle correct

on the bosses at Gold King.

The

pictures below show the “test” cone with top of the cone being 3 ¼”, the bottom

of the cone being 4 3/8” and the height being 5”. This cone matches the

smallest boss diameter at Gold King. We will install shims to verify each of

the boss dimensions using the shims to verify if this cone can be used for all

5 stamps.

The

final step in this project is to communicate with foundries that will still

cast shoes and dies. We are considering two Foundries that could do the job. I’m

estimating the cost should be between $2 and $3 per pound for cast steel, coming

to about $150 each

Kit’s

Foundry & Machine Inc Anaconda

Foundry Fabrication Company AFFCO

779 E.

1100 N 1015

East Sixth Street

Shelley,

ID 83274-5222 Anaconda,

MT 59711

To

give you an idea of the cost of a shoe and die back in the day, December 23,

1913, cost $21.00 each for a chrome shoe and a die. The

shoes we are looking at will be made from the cheaper cast steel.

THE END